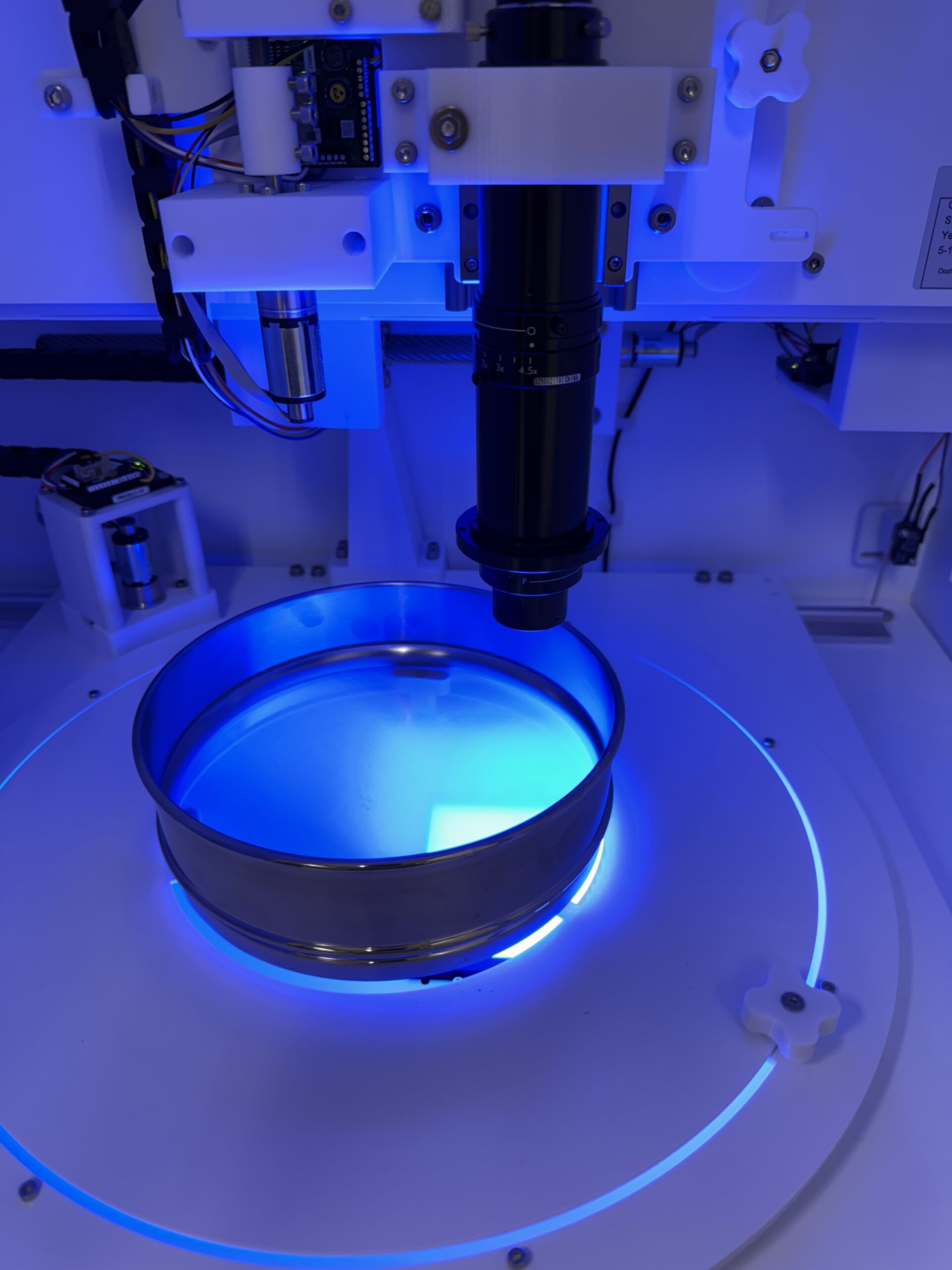

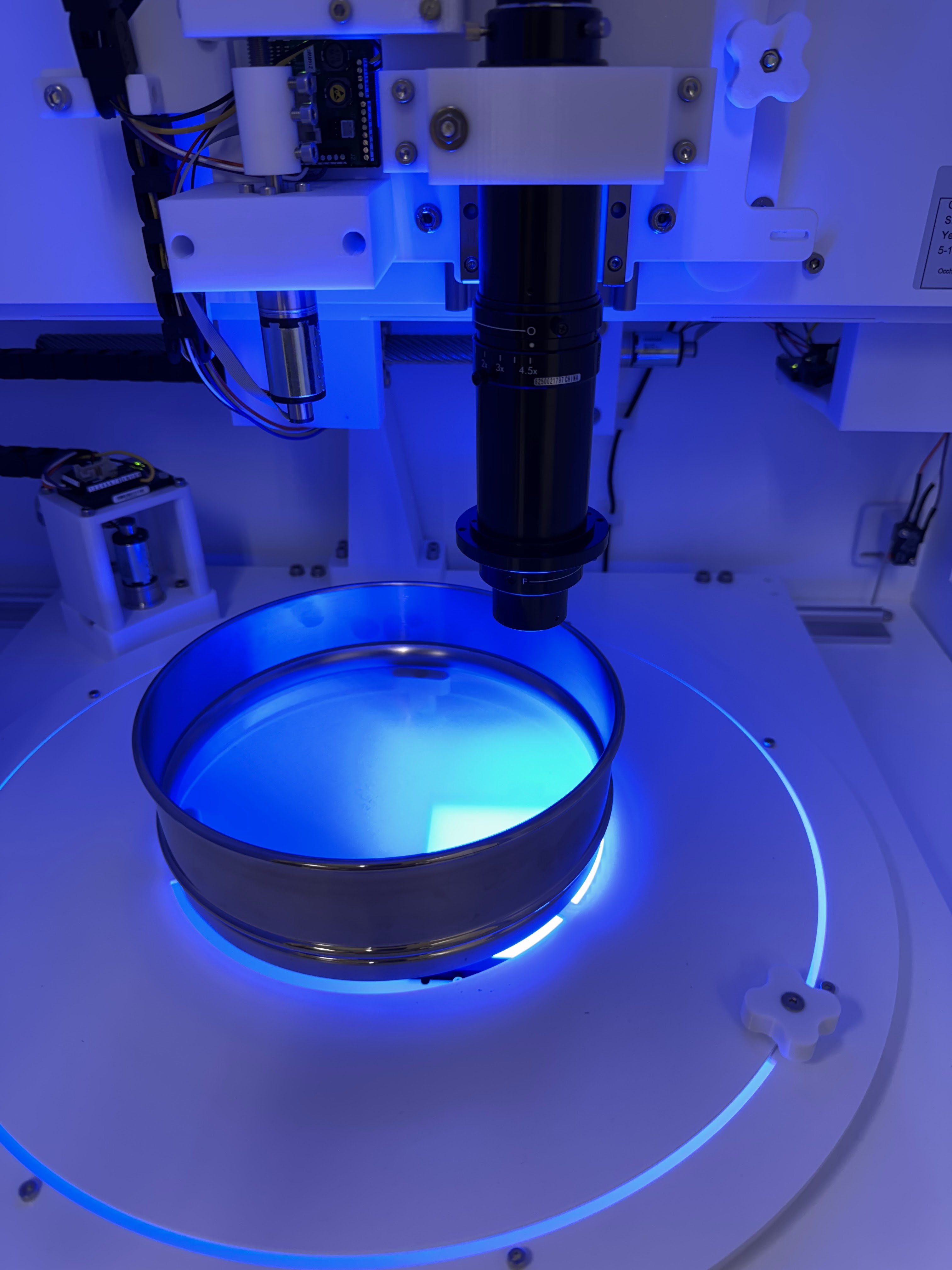

We have acquired a dedicated sieve calibrator that automatically, quickly, and reliably measures sieve openings and the thickness of the material between them.

Why is this important?

- We measure more openings in the same amount of time

- We measure with a more even distribution of openings across the sieve surface

- Consistent automatic edge detection of openings

- Upon request, we add a compliance statement to ISO 3310 or other relevant standards to the certificate

Thanks to the larger number of measured openings and their more even distribution, the calibration results now provide even better overview of the sieve’s condition, enhancing the reliability of sieving results.

Laboratory sieves compliant with the ISO 3310 standard are used to assess the composition of materials consisting of particles of different sizes. Simply put, they help determine how fine or coarse the particles are and what proportion of, for example, sand, gravel, metal powder, or pharmaceutical powder consists of particles of different sizes. Since the sieves are manufactured with precise and controlled aperture sizes, they ensure consistent product quality and make results comparable across different laboratories and factories.

Introductory campaign for sieves manufactured according to ISO 3310 standard

To introduce this new service, we are offering a discount until the end of the year:

- 🔹 For 1–4 sieves → -10%

- 🔹 For 5 or more sieves → -20%

The campaign is valid until 31.12.2025.

Contact us HERE or request a quote: